Your cart is currently empty!

When it comes to the performance and reliability of your water pump, the oil seal—also known as a shaft seal or rotary seal—plays a small but critical role. Often overlooked, this component is essential for keeping lubricants in and contaminants out, ensuring your pump runs smoothly for years.

In this article, we’ll explain what an oil seal is, how it works, common failure signs, and why choosing the right one matters.

1. What Does a Water Pump Oil Seal Do?

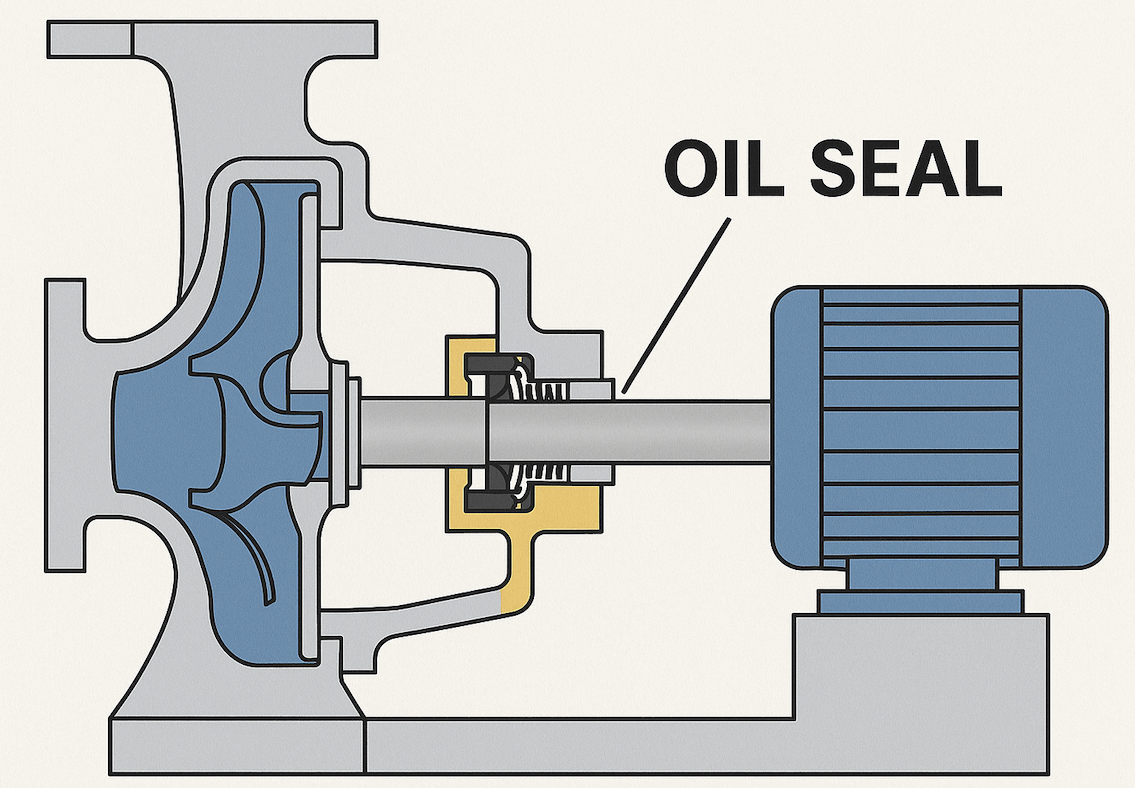

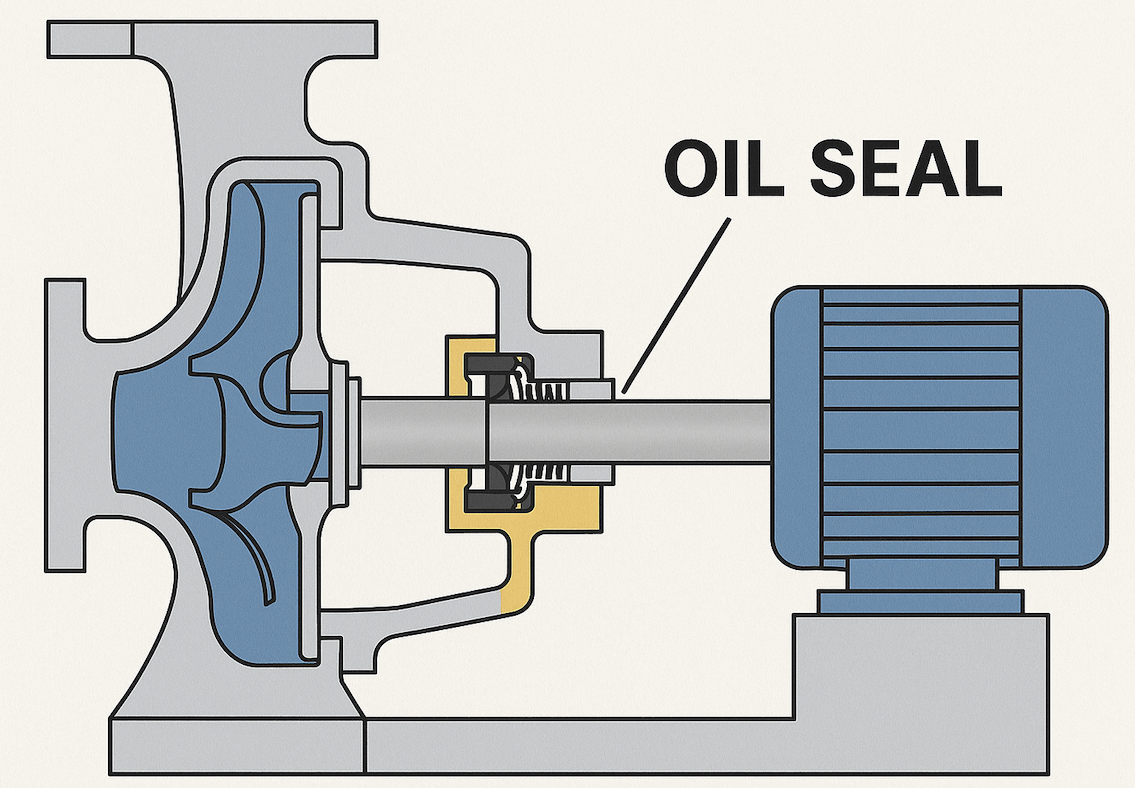

The oil seal sits between the pump shaft and the pump housing, acting as a barrier between internal oil and the outside environment. Its main purposes are:

- Prevent Oil Leakage

Keeps lubricating oil or grease from leaking along the rotating shaft. - Keep Out Contaminants

Stops water, dirt, and dust from entering the bearing chamber and damaging internal components. - Maintain System Pressure

In certain designs, it helps maintain oil pressure inside the pump assembly.

Without a functioning oil seal, you may face oil leakage, noisy operation, or even bearing damage—all of which can lead to costly downtime.

2. Structure of a Typical Oil Seal

A standard oil seal is made up of three key parts:

- Metal Case – Provides structural strength and secure fitment.

- Rubber Sealing Lip – The flexible edge that makes direct contact with the shaft to create a tight seal.

- Spring (Tension Spring) – Maintains constant pressure on the sealing lip for consistent performance.

These three elements work together to ensure the pump shaft remains sealed, even under continuous rotation and varying pressure.

3. Common Materials Used

Choosing the right material depends on the pump’s working environment:

- NBR (Nitrile Rubber): Cost-effective and oil-resistant; ideal for general-purpose pumps.

- FKM (Viton / Fluoroelastomer): Excellent for high-temperature or chemical applications.

- PTFE (Teflon): Offers the best resistance to friction, chemicals, and heat—often used in industrial-grade pumps.

4. Where Is the Oil Seal Located in a Pump?

In most centrifugal and submersible water pumps, the oil seal is located:

- Between the pump shaft and the motor bearing housing;

- Around the outer side of the bearing seat; or

- Between the lower bearing and water chamber (in vertical configurations).

In more advanced pumps, a mechanical seal may be used instead, which performs a similar function but is suitable for high-pressure and high-speed environments.

5. Signs of Oil Seal Wear or Failure

Watch out for these common symptoms that your oil seal may need replacement:

- Visible oil leakage near the motor or shaft

- Unusual noise from bearings

- Reduced pumping efficiency

- Overheating of the pump

- Dust or debris inside the pump housing

If you spot any of these signs, inspect the seal immediately to prevent more serious damage.

6. How to Extend Oil Seal Life

- Keep the shaft surface smooth and free of scratches.

- Avoid misalignment during installation.

- Use quality lubricants recommended by the manufacturer.

- Choose seals made from materials suitable for your operating temperature and chemical exposure.

7. Conclusion

The oil seal may be a small part of your water pump, but it plays a huge role in maintaining reliability and performance. Whether you’re maintaining a household pump or running an industrial pumping system, always ensure your oil seals are in good condition.

At EIIMan, we provide high-quality water pumps, spare parts, and oil seals designed for durability and efficiency. Contact us today to find the right seal for your pump model!

Leave a Reply