Your cart is currently empty!

When choosing a motor for your water pump, efficiency, reliability, and cost are key factors. In recent years, permanent magnet (PM) motors have become an attractive alternative to traditional induction motors. But what makes them different, and why should you care? Let’s break it down.

Working Principle

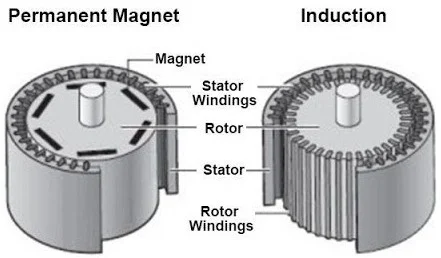

Traditional Motor (Induction Motor):

Relies on electromagnetic induction. Current flows into the stator, creating a rotating magnetic field that induces current in the rotor, which produces torque. This process involves energy loss in the form of heat.

Permanent Magnet Motor:

Uses high-strength permanent magnets in the rotor instead of induced current. This eliminates rotor copper losses, making the motor inherently more efficient.

Energy Efficiency

Traditional Motor:

Efficiency typically ranges between 85–90%. Energy is lost in the induction process, especially at partial loads.

Permanent Magnet Motor:

Efficiency can exceed 95%. Because of direct magnetic coupling, PM motors maintain high efficiency across a wide load range, making them ideal for variable-speed pumping systems.

Size and Weight

Traditional Motor:

Bulkier and heavier, since they require more copper windings and larger rotor structures.

Permanent Magnet Motor:

More compact and lighter for the same power output, which allows water pumps to be smaller, easier to install, and more space-efficient.

Control and Performance

Traditional Motor:

Control is relatively simple, but performance at variable speeds is less optimal. Efficiency drops significantly at partial loads.

Permanent Magnet Motor:

Works best with advanced variable frequency drives (VFDs). Offers smooth control, higher torque density, and better performance at variable speeds—perfect for modern smart pumping systems.

Cost Considerations

Traditional Motor:

Lower upfront cost, widely available, and proven over decades of use. However, energy consumption over time can increase operational costs.

Permanent Magnet Motor:

Higher initial cost due to the use of rare-earth magnets, but savings come from reduced energy bills, longer lifespan, and less maintenance. Over the pump’s life cycle, PM motors often prove more cost-effective.

Applications in Water Pumps

Traditional Motor:

Still widely used in basic pumping applications where initial cost is the primary concern and the pump runs at a constant speed.

Permanent Magnet Motor:

Preferred in energy-sensitive environments, such as municipal water systems, HVAC, and industrial pumping, where variable speed and efficiency directly impact operating costs.

The choice between a permanent magnet motor and a traditional motor comes down to short-term vs. long-term value. If upfront budget is limited and efficiency is not a major concern, traditional motors still work. But if you want energy savings, compact design, and long-term cost-effectiveness, a permanent magnet motor is the smarter choice—especially for water pumps that run continuously or under variable loads.

Leave a Reply